Written By: Brad Campbell | September 9, 2021

According to some estimates, nearly 1/3 of homes built before the year 1990 in Miami-Dade County are at risk of major storm damage from a hurricane or tropical storm. This amounts to nearly 1,000,000 single-family homes in a major hurricane zone.

After Hurricane Andrew hit Florida in 1992, Miami-Dade County adopted stricter building codes to construct homes and commercial buildings to higher standards in terms of storm damage protection.

Whether you’re making hurricane mitigation upgrades to an older property or building a new facility to Miami-Dade’s hurricane building code standards, one way to protect vulnerable windows and doors is by using hurricane glass.

In this article, we’ll explain in more detail what hurricane glass is and what testing standards it needs to meet in order to be eligible for use in Miami-Dade County.

“Hurricane glass” is a term that can refer to different types of impact-resistant glass and glass-like panels. These products are known more broadly as “security glass” because they can also protect against other security threats, such as forced entry and burglary.

Two of the most common types of security glass products that can be used for hurricane protection are laminated security glass and polycarbonate glazing shields.

We prefer the latter because you can achieve a much higher level of protection with a relatively thin, light panel of polycarbonate than you can with security laminates.

The purpose of hurricane windows is to:

Hurricane windows can either be installed during the construction of a new building or retrofitted into or onto the existing framing to bring an older building up to modern storm damage protection standards.

However, it’s important to note that companies and marketers sometimes refer to products as hurricane glass when they have not actually passed the level of impact testing required to be approved for use as a hurricane damage mitigation barrier.

Hurricane testing for glass is a type of impact testing in which we simulate windborne debris striking a window as if it were thrown into the glass (or other material) by hurricane-force winds.

In addition to testing a hurricane window’s impact resistance, hurricane testing also measures its ability to withstand the rapid decreases and increases in pressure within the building that occur during a hurricane.

This type of impact testing and pressure testing must be carried out in a laboratory in accordance with Miami-Dade County hurricane code requirements in order for any hurricane glass to meet the standards set forth by the county’s code.

All windows being tested to Miami-Dade County standards have to undergo a series of large missile impact tests. These missiles are typically 2x4s shot out of a steel piping cannon, which uses compressed air to propel them.

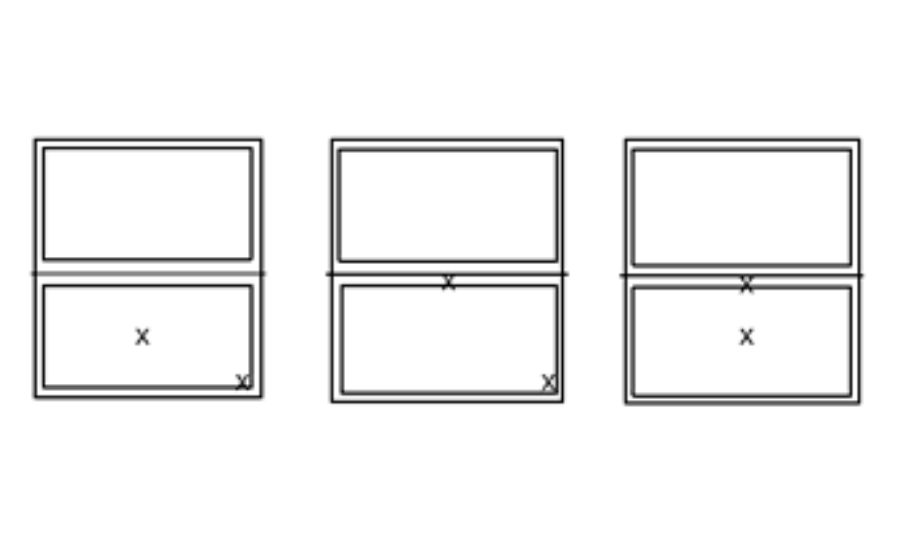

For a piece of hurricane glass to pass the test, it must withstand impacts from the 2x4s in 2 different places on the surface of the glass. Once the first window passes the test, it is repeated on 2 more specimens of the same window to ensure consistency and accuracy.

Image via https://www.miamidade.gov/

It’s also important to note that manufacturers should always test the largest pane of glass or other material that they intend to supply. If the largest window resists the impact, it is assumed that any smaller versions will have the same or better impact resistance.

After the impact test, the windows are pressure tested under various positive and negative pounds per square foot (PSF) loads to make sure they won’t break apart or become dislodged due to the internal structural pressure changes in a hurricane.

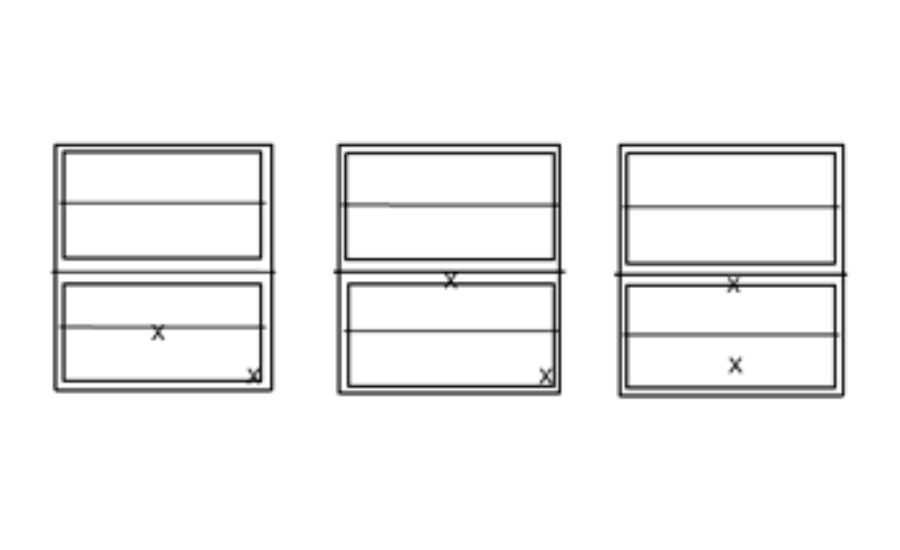

Miami-Dade hurricane code testing at a glance:

Image via https://www.miamidade.gov/

Spoiler: It Met Miami-Dade Hurricane Glass Testing Standards!

We recently put our containment-grade polycarbonate glazing shields, ArmorPlast™ AP25, to the test at the Intertek Building & Construction testing facility.

We were confident in its virtually unbreakable strength, but we needed to make sure it was up to the task of withstanding hurricane damage in Miami-Dade County.

The specimens we provided were evaluated in accordance with the following:

All 3 of the polycarbonate panels we tested receive 2 impacts from 9.5-pound, 96-inch-long 2x4s, propelled into the glazing shields at speeds between 49.6 and 50.4 feet per second.

And, we’re happy to say, all 3 specimens passed the impact test with flying colors! We then tested the AP25’s pressure resistance under +40 and -40 PSF loads, and it passed again!

No signs of penetration, rupture, opening, or failure were observed on any of the polycarbonate glazing shields during any of the tests.

ArmorPlast™ AP25 met the requirements of:

So, what exactly does this mean? AP25 polycarbonate panels can be used in new construction or retrofitted onto existing structures in Miami-Dade County for use as hurricane windows.

Additionally, AP25 passed the Forced Entry Resistance test, per ASTM F588. It was shown to completely deny any type of forced entry attempt.

Contact our team of security experts today for a consultation. Or, have your local glass contractor in Miami-Dade County call us to discuss how we can help them reinforce your property against hurricane damage with ArmorPlast™ AP25.

HOW CAN WE HELP YOU?